Digitally Testing Code with Simulation Software

Siemens TIA Portal Simulation Software

Terrance Brinkley, from Patti Engineering, is here to explore how Siemens TIA Portal’s built-in simulation software, PLCSIM, and WinCC Runtime Advanced can be used to simulate PLCs and HMIs, enabling programmers to detect and fix issues before deployment, resulting in error-free industrial automation and smooth system start-ups.

When and how can you use industrial automation simulation software?

Anyone who has programmed, in industrial automation or other areas, will admit their first draft of the program is never perfect. Programmers try to review their code as best as possible, but reading lines of code is not an easy way to detect issues. Usually, most issues are discovered once the programming “goes live” in a machine or a software package. Discovering problems when the code is running can be quick and straightforward. However, code bugs can be harmful to data, machinery, or even people. In industrial automation, one way to detect problems is to simulate the program before installing it in a machine. Most PLC programming environments include a platform to simulate PLC programs before install. This digitalized approach prevents potential problems caused by code bugs. With Siemens TIA Portal, PLCs can be simulated using the built-in simulation software PLCSIM and WinCC Runtime Advanced can be used to simulate HMIs.

How to Launch PLC Simulation in TIA Portal

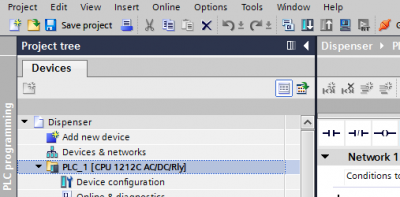

To launch PLCSIM in TIA Portal, simply select the PLC you wish to simulate, then click the “Start simulation” button on the toolbar.

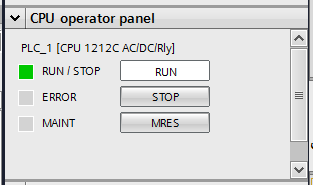

When simulating PLCs with PLCSIM in TIA Portal, the PLC can be switched between run, stop, and memory reset exactly like an actual PLC.

Real Time Code Monitoring and Manipulation

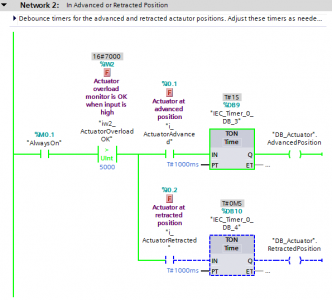

Code blocks can be monitored exactly as if they were monitored on a running PLC. Using force or watch tables, data can be modified and input can be triggered as if it was actual input from a physical machine. The example below shows a network from a simulated PLC with the inputs forced to specific values. The red “F” indicates that an input is being forced.

The ability to run code without a physical PLC or machinery can be a great benefit to debugging and can help catch issues before they cause expensive damage or downtime. With Siemens PLCSIM and TIA Portal, simulating and monitoring code is quick and easy.

Streamlining Industrial Automation: Simulating HMIs for Efficient Setup and Debugging

Another important component in many industrial automation projects is the human-machine interface, or HMI. These screens can be very detailed and complicated to set up. Usually, starting up a machine can include a lot of HMI debug. Onsite debug on a customer floor can be costly to the integrator and the end customer. As with PLCs, simulating the HMI programs before install can drastically reduce glitches and startup time.

How to Activate WinCC Runtime Advanced to Simulate an HMI

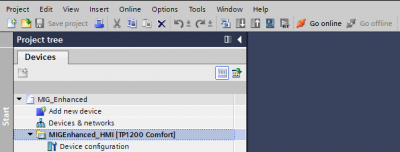

To simulate an HMI, select the device from the project tree, then click the “Start simulation” button on the toolbar.

Using WinCC Runtime Advanced with TIA portal, HMI debug can be done in advance to reduce costly onsite debug time. If setup correctly, the simulated PLC and HMI can be connected to fully simulate a system without ever leaving your desk. This helps ensure system start-ups go smoothly without any major issues.

TIA Portal’s PLC and HMI Simulation Software Recap

In conclusion, the use of Siemens TIA Portal’s simulation software, PLCSIM, and WinCC Runtime Advanced presents a powerful digitalized approach for testing and debugging PLCs and HMIs in industrial automation projects. By allowing programmers to detect and fix issues before deployment, this simulation capability ensures error-free automation and smooth system start-ups. With the ability to simulate code without physical machinery, costly damages and downtime can be prevented, while also reducing the need for expensive onsite debugging. By leveraging this advanced simulation technology, engineers can confidently optimize their programming and design processes, leading to more efficient and reliable industrial automation solutions.

Siemens TIA Portal PDF serves as a helpful resource to learn more.

Siemens PLM Plant Simulation Software – Tecnomatix®

In addition Siemens TIA Portal’s simulation software, PLCSIM, and WinCC Runtime Advanced discussed in this article. In our blog on Siemens Tecnomatix® Plant Simulation software you can explore how creating a “digital twin” of an entire facility can optimize production throughout your facility.

Siemens TIA Portal and Tecnomatix® Simulation and Project Assistance

Ready to optimize your industrial automation processes and ensure error-free system start-ups? If you need help or guidance in implementing Siemens Tecnomatix® Plant Simulation or Siemens TIA Portal’s simulation software for PLCs and HMIs, don’t hesitate to contact Patti Engineering. Our experienced team is here to assist you in digitally testing your code, detecting potential issues, and achieving smooth and efficient industrial automation. As a Siemens Solution Partner our capabilities are extensive across a broad range of industries. Reach out to us today to streamline your automation projects and enhance your productivity.

Editor’s Note: This post was originally published in August 2017 and has been updated for comprehensiveness and clarity.

Related categories: Blog Industry 4.0 / Digitalization Siemens