FAQs on IIoT

You can hardly open a trade publication or check a conference agenda without bumping into “IIoT.” But the third time we heard someone (who is technically competent and pretty savvy) ask what it was, we figured it was time to step back and break it down.

What’s IoT?

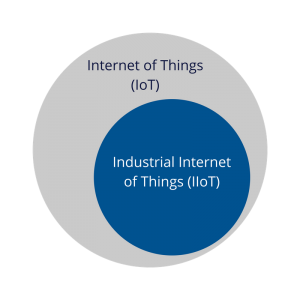

IoT, or Internet of Things, is the ability for things to “talk” to other things. You may have heard it called “connected devices” or “smart devices.”

What’s IIoT?

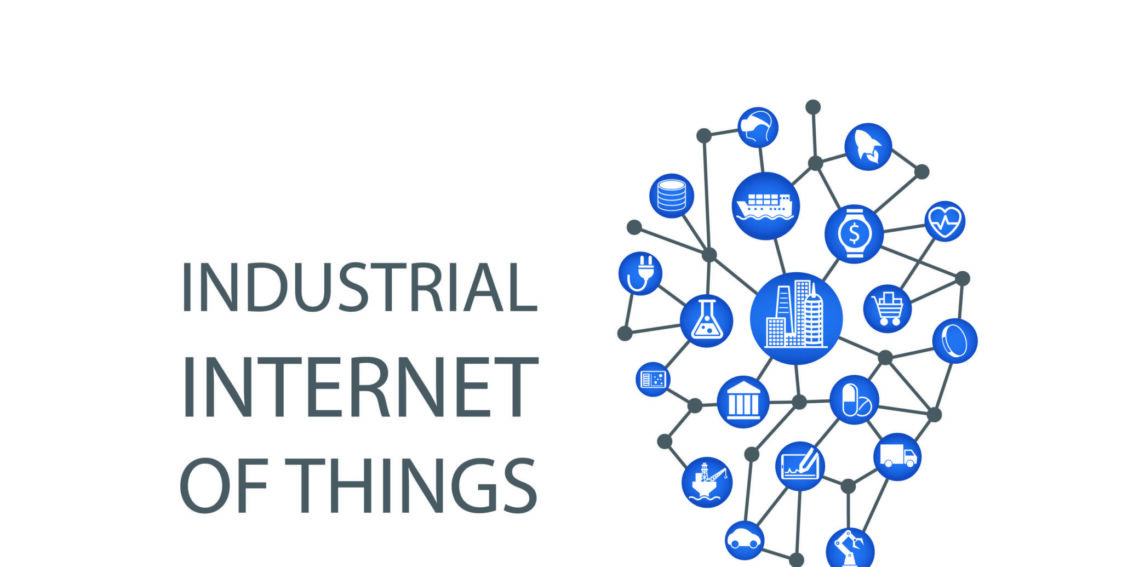

IIoT is Industrial Internet of Things. It’s the aggregation of sensors, communications, data storage, and analytics in an industrial environment.

So IoT and IIoT are basically the same thing?

Yes. IIoT just distinguishes itself as the industrial application. All IIoT is IoT, but not all IoT is IIoT.

Is IIoT the same as Industry 4.0 and Digitalization?

Yes and no. IIoT is often talked about in conjunction with Industry 4.0 and Factory Digitalization. Sometimes, the terms are even used interchangeably, although that isn’t 100% accurate.

Digitalization is one element of IIoT – moving from manual methods to digital ones. One example of this is moving from push-button controls to HMIs.

IIoT is one arm of Industry 4.0. The other advances that Industry 4.0 encompasses- simulation, digital twinning, additive manufacturing, big data, augmented reality, cloud computing, autonomous robots, and of course cyber security – are all related to IIoT.

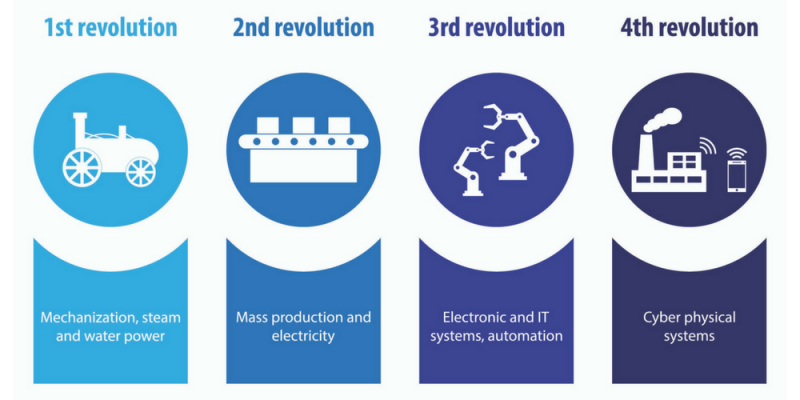

Industry 4.0 is sometimes called the Fourth Industrial Revolution. It’s a wave of advances, that, together, are changing the way industry works. The first industrial revolution is the era we think about in the early 1800s which introduced machines. The second took place in the early 1900s and introduced electricity and the assembly line. The third started with the introduction of the PLC, introducing automation and IT. While the first three revolutions were spaced roughly a century apart, this fourth revolution is coming about 20 years later – practically on the heels of the last one! Some academics consider the third and fourth waves as part of the same overall trend. We probably won’t know until time gives us some distance, but the implications are the same: Things are changing in our industry- and fast!

Why is IIoT suddenly the most popular topic on the block?

It’s a snowball effect. Prices for sensors and data storage are going down, making it all more accessible. More adoption is leading to more innovation, which is making the overall effect greater and more exciting.

What’s so great about IIoT, really?

Besides the cool/geeky factor, the two main benefits of IIoT are data collection and analytics. In this way, it offers a very similar advantage to that of a SCADA system. The difference is in the scope, and therefore, the potential of the data collection. SCADA is a centralized system that does not have to be connected to the internet. It usually collects a set amount of data for a set purpose. With IIoT, there essentially isn’t a limit to the amount or type of data that can be collected or the length of time it can be stored for.

Do I really need almost infinite data?

Not always, but you might not know what you need until you do. One example of a situation where this would be helpful is if there’s a delay between a problem occurring and a problem being noticed. For instance, a product recall might happen months or years after production. Having more data than you knew you needed would greatly improve traceability and hopefully limit the scope of the recall.

Aside from traceability, this amount of data allows for analysis of all kinds of metrics. The potential of data collected through an IIoT system is bigger picture than the day-to-day operation of a plant. It could be used to make plants far more efficient over time.

(Relatedly, this author is old enough to remember when smartphones were considered overkill.)

What’s the drawback?

The challenge here is that with this much data, we need a way to make sense of it. Otherwise, we might be just swimming/drowning in it. Siemens has recently introduced a platform called Mindsphere to handle all of this data. It has an open API and will give plants the ability to aggregate and analyze their data using pre-written apps or building apps of their own. We’ve been working with them to develop apps for the platform, and we have to say: It does offer a lot of possibility. You can read more about it, here: Siemens Mindsphere.

I’m not ready for this yet.

That’s okay! You don’t have to rebuild your entire facility to reap benefits from this new wave. Lots of facilities have already adopted IoT technology without even knowing that’s what it was called. HMIs, ethernet enabled radios and devices… Knowing about the potential for a totally connected facility can help you make better decisions as you make smaller upgrades now.

I am definitely ready for this now.

Related categories: Blog Industry 4.0 / Digitalization