Patti Engineering Upgrades Motion Control to Double Production Speed for Customer in First Month

Founded in 1954, Thermon is an industry leader in the specialized field of heat tracing technology. Thermon provides products such as flexible heating cables, heat tracing compounds and tubing bundles to serve as an external heat source to pipes, vessels and instruments for the purposes of freeze protection, temperature and flow maintenance, environmental monitoring, and surface snow and ice melting.

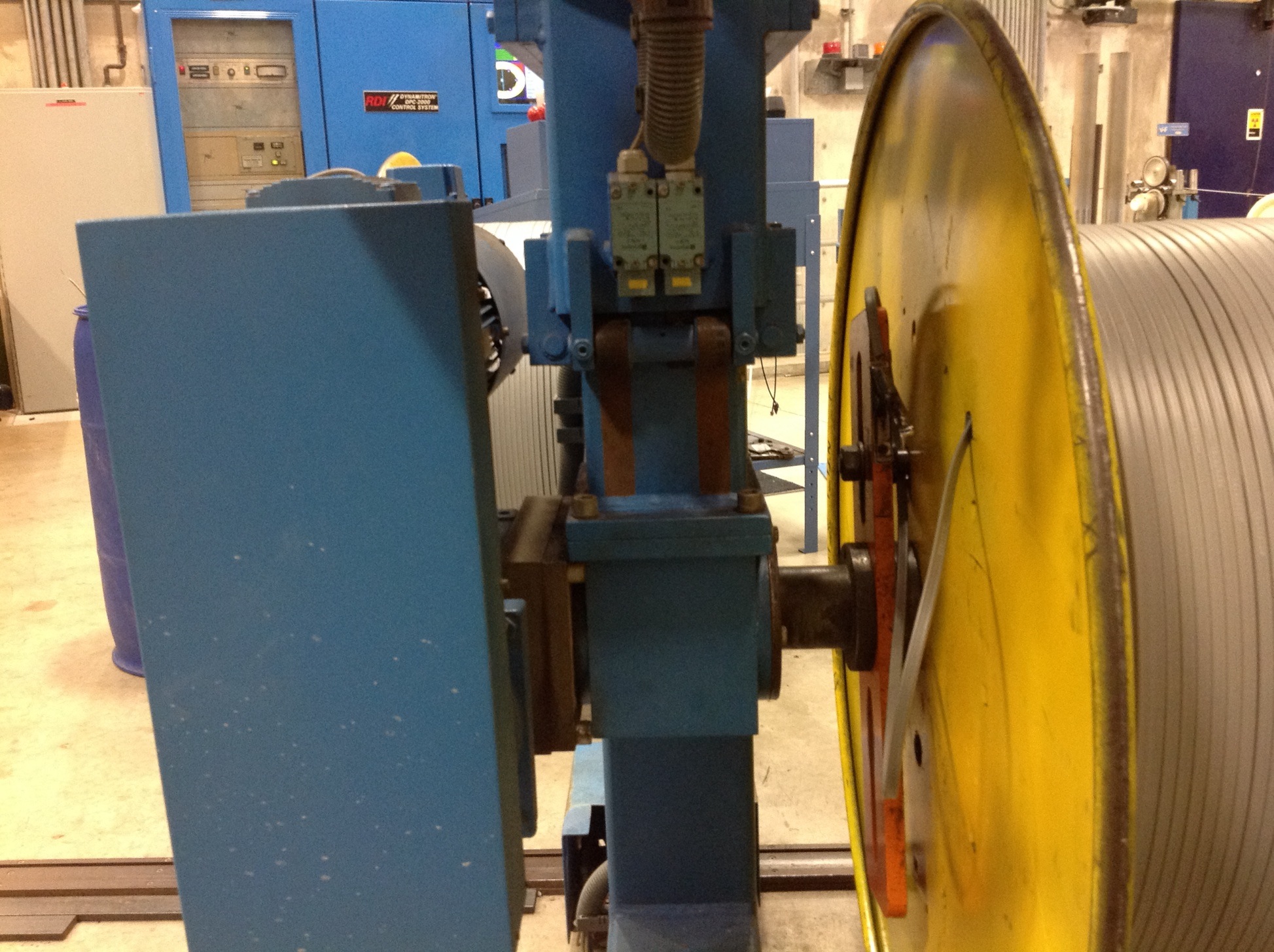

Thermon’s San Marcos, TX manufacturing plant is highly automated, and the heart of the operation is the Electronic Cross-Linking Facility (ECLF). The machine unwinds cable into an electron beam field that gives it a specific dose of radiation. This changes the molecular properties of the cable. Then it is re-wound onto another cable reel. Cross-linking enhances the thermal, chemical and electrical stability of Thermon’s low-temperature self-regulating heater cables. All end products produced at Thermon’s San Marcos plant must go through ECLF un-coiler and re-coiler stations for the finishing process.