What is UHF RFID?

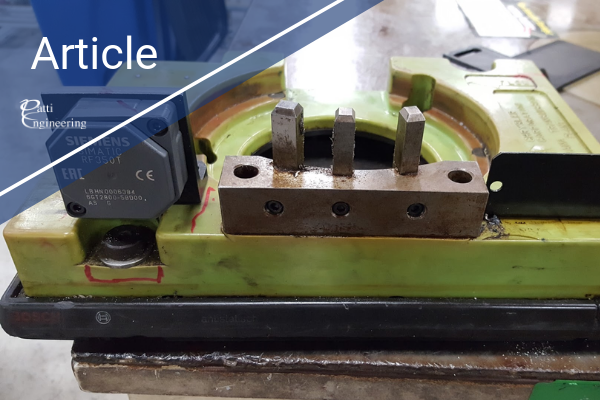

Ultra-high frequency (UHF) RFID technology utilizes radio propagation or backscatter as the means for reading/writing data to transponders or tags. Worldwide harmonization efforts have been made to make UHF RFID globally compatible for the efficiency benefits of intercompany supply chains. Because different countries have differing radio spectrum allocations, UHF RFID tags are often, but not always, designed to function in multiple radio bands. In FCC regulated jurisdictions, UHF RFID operates in the radio spectrum between 902 MHz and 928 MHz. While this band range provides UHF RFID systems with larger read ranges and higher data transfer rates than the LF or HF RFID, for instance, it transfers less data overall.

The UHF RFID readers can be programmed to filter out unwanted tags and tuned to reduce the number of missing and duplicate errors within the system.

When to use UHF RFID?

Automated UHF RFID solutions work well for variable positioning and long-range reading applications. With the ability to read multiple tags at a time, it can be a tool for lIot tracking and other Industry 4.0 applications.

It is important to note that large metal objects and liquid containers inside the read field can create issues with reflected fields and holes. Completing site surveys can help to identify and mitigate these issues early on.

Benefits from UHF RFID

While UHF RFID systems do require additional programming compared to HF RFIDs, they offer a lot more flexibility in how the tags are presented to the readers.

Challenges of UHF RFID

Unlike the simple close proximity reading environment of HF RFID, the reading environment or “interrogation zone” of UHF RFID requires very careful planning. Interrogation zone design is heavily influenced by the application and the physical environment in which the interrogation zone is to be located.

Depending on the application, an interrogation zone may require multiple antennas or even multiple readers. Applications with multiple antennas may require the use of cable splitters and/or multiplexers. Application designers will need to consider the power transmission levels, cable losses, insertion losses of connectors and splitters, antenna gains, and regulatory limitations. This process is often referred to “Link Budgeting”. Proper, and legal, interrogation zone design is best accomplished by experienced and qualified application designers.

Before interrogation zone design is performed, proper transponder/tag selection must be made. Tag selection is nontrivial. Poorly selected tags can cause an UHF RFID application to fail to achieve investment objectives. Some tag selection considerations include the required size of the tag, method of attachment to the tracked item, orientation of the tag with respect to the orientation of the radiating field of the antennas, and environmental considerations such as exposure to heat, harsh chemicals, etc. Other tag selection considerations include electronic product code (EPC) and user memory needs, read/write sensitivities and speeds, and the capability of being killed or locked.

Perhaps, the main challenges of UHF RFID are the many unexpected and normally unseen effects to the radio wave propagation from reader to tag and back from tag to reader. UHF RFID radio waves can be reflected by metal obstacles and absorbed by liquid obstacles. Multipath propagation is when broadcasted signals from the reader (and the tag by consequence) arrive at the receiver part of the reader (or the tag) from different directions. When these signals arrive in phase with each other they create a condition referred to as constructive interference. When this constructive interference occurs outside of the planned interrogation zone, this can cause the reading of unexpected tags. When these signals arrive out of phase with each other they can create a condition referred to as destructive interference. When this destructive interference occurs inside of the planned interrogation zone, this can cause dead zones to emerge where expected tags are not able to be read or written. One way to visualize destructive interference is to consider the interrogation zone as a block of Swiss cheese where the dead zones are the holes in the cheese.

There are many more challenges and considerations to evaluate in planning a successful UHF RFID application. The use of experienced and qualified UHF RFID application designers will be necessary except for the rarest and simplest applications.