There are plenty of companies that can program automation systems. And there are plenty of companies that can perform data analytics and understand digitalization. But Patti Engineering is one of the few companies that is an expert in both manufacturing and digitalization.

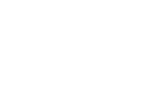

We have a deep understanding of manufacturing operations and the challenges and opportunities that manufacturers face, and we understand what it takes to undergo a digital transformation and make it work for the client. In other words, we’ve bridged the gap between OT (operations technology) and IT (information technology).

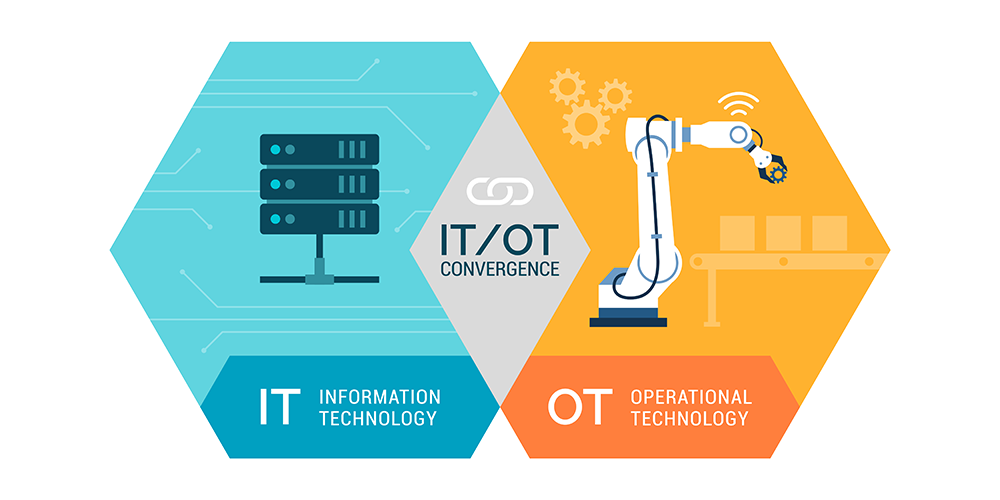

We also understand that a digital transformation can seem daunting, and it is a big undertaking. So, we start by taking a first step – looking at an area where improvement is needed, whether it’s a “big” problem that you can’t solve with traditional methods or a recurring problem that you just can’t shake. We guide you through the digitalization process to address that problem, and then help you refine your digitalization tools and processes and expand them to other areas.