Ancor Labeling

Increasing production on a label packaging operation

Increasing production on a label packaging operation

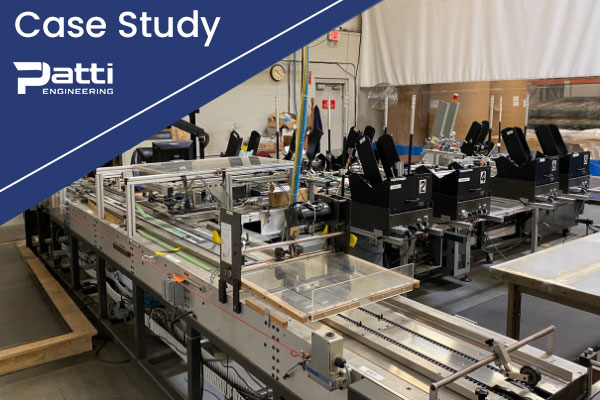

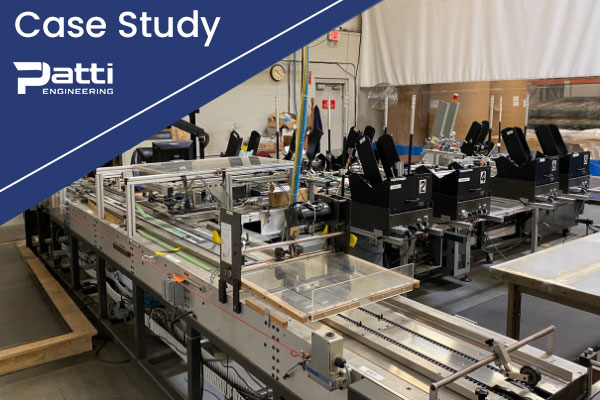

Back in 2005, Ancor teamed up with Patti Engineering to create a label packaging line and the line has been running ever since. Over the years, Patti Engineering has completed minor upgrades on the line, but the majority of the original hardware and software was still being used 15 years later.

Ancor wanted to increase production, but was finding that the aging line was running over 30% slower than it has in the past. This led to an investigation by the Patti Engineering team to find the root of the problem and ultimately get the line back running at the necessary rate.

Recently, Ancor began running their label packaging line at full capacity but found that the system was no longer producing at the same rate. With production deadlines, Ancor reached out to Patti Engineering to assist with diagnosing the cause of the low throughput.

After conducting an in-depth production analysis, Patti Engineering attributed the slow production rates to the out-of-date hardware and software. The system was still running with the original hardware, and over time old hardware can become inefficient and start causing delays in production throughput. Patti Engineering and Ancor then devised a plan to replace the outdated equipment and update the software to streamline the process.

Patti Engineering started with replacing the old hardware with a new control panel. The Allen Bradley SLC 5 PLC was replaced with a Siemens PLC and the LPAS HMI was replaced with a Siemens Comfort Panel.

The communication for the label packaging line was overly complicated for today’s standards. The system was using both VB6 and VB.NET to set up communication from the PLC to the network database. Patti Engineering simplified the communication structure by installing the Ignition SQL Bridge software to handle all handshaking between the PLC and the network. This has helped to consolidate the program into one software which speeds up debugging time and improves maintenance.

With the updated technology, Ancor saw a production increase from 1500 back over 2100 packages an hour. The increase in production rate allowed Ancor to meet their production deadlines. The updated technology has made the system more reliable and a lot easier to maintain.

The upgrades completed in this project also helped to better utilize previous upgrades completed by Patti Engineering. A few years ago, Patti Engineering completed an upgrade for the vision system. Now, the vision system is able to format the data from the barcode as well as specify the barcode type that is being scanned.

This has allowed the system to make better decisions based on the data read in.

Michigan Director of Operations

With a natural affinity for control systems integration, Terrance Brinkley has been an asset to Patti Engineering since 2004 and now leads his team as the Director of Michigan Operations. A native of Pontiac, Michigan, Terrance graduated from Michigan State University with a Bachelor of Science degree in both Electrical Engineering and Computer Engineering.Patti Engineering utilizes trusted advisor status and proven expertise to research and develop a solution for an integral verification station for a medical device manufacturer.

Fair Oaks Ranch hired Patti Engineering to upgrade their servers from Windows 7 to Windows 10.

A local automotive manufacturer purchased three leak test systems from an OEM.

Take the first step towards optimizing your business operations and staying ahead of the competition.