6 Things to Remember When Setting Up a Temperature PID in Siemens TIA Portal

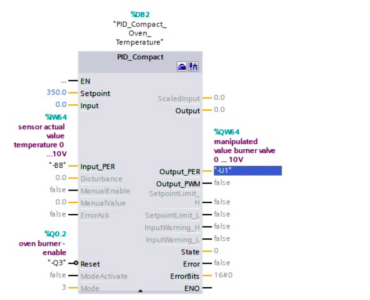

When working with applications where precise temperature and humidity control are vital, such as paint shop air supply systems or industrial ovens, PID temperature tuning becomes a non-negotiable step. The tuning process involves configuring Siemens PID Temperature Technology objects in a Siemens PLC program, including selecting the thermal measurement device, parameter setup, and PID FB technology object activation. Choosing the right tuning mode is essential for optimal performance, while manual initiation of control helps guarantee hassle-free temperature control.

Here are six best practices and tips when using a Siemens PID Temperature Technology object to control your heat device inside of your Siemens PLC program:

- Before doing anything, choose the correct thermal device that will be used to measure the temperature. Is it a thermocouple, a thermistor, a resistor? With that, set up the correct parameters and units (Fahrenheit or Celsius). This is found in the analog card properties, under the hardware device configuration

- Set the cyclic interrupt, OB30, to a reasonable interrupt time, such as 100 – 500ms

- Your technology object, the PID FB, should always be enabled

- Before starting the tuning algorithm, determine what tuning mode will be used.

- Pre-tune – used if the temperature difference between actual and setup temperature is greater than 20 degrees

- Fine-tune – used when the temperature difference between actual and setup are within a few degrees. For systems exposed to varying external conditions across seasons, fine-tuning might be necessary to adapt to temperature fluctuations, ensuring consistent control throughout the year.

- Note: You might want to manually start the PID to start warming up the device before switching to pre-tune or fine-tune. Once auto-tuned, the system should work as needed, but monitoring is required.

- If you have multiple PID loops and the devices that are being controlled are similar, you can manually enter the PID values from a device that has already been tuned

- This is found under the Advanced Settings section in the configuration folder for your technology object

- Ensure that you have a way to shut down the heat device if necessary, in case of a malfunction. In such a case, use a heat switch button (externally wired or on the HMI) to enable/disable the heat device(s). This way, if the PID loop goes awry, you won’t run the risk of melting a part or burning up a heating element.

Choosing between pre-tuning and fine-tuning plays a major role in optimizing performance, ensuring that your temperature control system operates at its best. Equally vital are manual control initiation and safety mechanisms, serving as safeguards against potential hiccups in temperature control. The advent of modern control systems has introduced the auto-tuning feature, simplifying the entire process and rendering it accessible to engineers, regardless of their level of experience.

The learning curve for this process isn’t as steep as you might expect, thanks to auto-tuning capabilities, which have substantially streamlined the complexities of PID temperature tuning. Following these simple steps will save time and prevent any headaches in setting up your PID loop to control your temperature device.

Related categories: Blog Control Systems Integration