Preview Our Upcoming eBook, ‘Common Considerations Integrating Robotics in Manufacturing’

Robotics can transform manufacturing, even in small-scale operations with budget and space constraints. Our upcoming eBook discusses common implementation questions around robotics integration.

The addition of robotics into manufacturing can seem daunting for someone with no familiarity of the subject. Robotics can seem like a solution only meant for state-of-the-art facilities operating with infinite budget, massive engineer support, and vast floor space.

Furthermore, for a manufacturer who’s never dealt with a robot in their production facility, the unknowns and therefore the perceived risks may outnumber the potential improvements. Robotics as a viable solution to production problems with real world constraints can feel out of reach, with too many unknowns and therefore way too much risk.

In reality, robotics is well suited to all kinds of circumstances, and especially those that arise from real world production environments. This includes, but is not limited to, limited floor space, budget constraints, and lack of onsite engineering support. Our upcoming eBook, Common Considerations Integrating Robotics in Manufacturing, discusses how a robotic system can be used to solve the problems that come from a multitude of challenging conditions with which smaller-scale operations struggle.

For example:

- A robot can do those dull, dirty and/or dangerous tasks that are hard to hire for.

- A robot can be the answer to a cramped cell with too much work for a single operator.

- A robot can double a welding cell’s throughput, acting as an additional hard-to-come-by skilled welder.

- A robot can easily do the simple heavy lifting work that’s challenging for humans to complete on a regular basis.

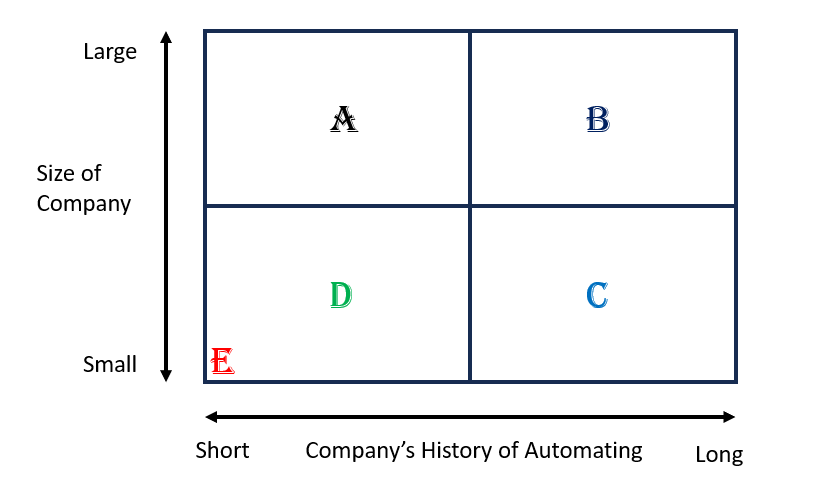

Common Considerations Integrating Robotics in Manufacturing addresses questions and concerns for manufacturers with little to no experience with robotics in their manufacturing process. In the diagram above, the eBook is written for those individuals in the D-E range of the graph.

The eBook is structured to provide the reader with a high-level overview of robotics in manufacturing, including the two major categories of robots to consider. Next, there is an in-depth discussion of a multitude of potential questions a newcomer may have. The answers for each question come from skilled robotics engineers with decades of experience integrating robotic solutions in the field. The answers will help the newcomer consider the addition of a robot as a viable solution for their production challenges, and guide them through the process of planning for automation.

More than 20 common newcomer questions have been compiled and addressed within Common Considerations Integrating Robotics in Manufacturing. The following is an example question and answer from the eBook:

How can I calculate a return on investment for automating my processes?

The decision to improve a process using automation begins with defining specific quantitative goals. Some examples include:

- Required parts per hour

- Percentage of material utilization

- Percentage of machine utilization

- Quality: reject reduction

Defining specific goal metrics allows for an easy calculation of a return on investment. For example, if one of the goal metrics is an increased number of parts per hour, this can be used to predict an increased number of parts per week, or per month, or per year. From there, that increase in parts may translate into an increase in revenue over that same time period. The revenue increase further defines the scope of the project, helping to define the best suited robot for the application, as well as projecting an appropriate overall budget and an expected breakeven time period.

Some further examples of questions addressed include:

- How long should I expect a system to last?

- What types of downtime should I expect?

- How will I find external qualified support for downtime issues?

- What kind of safety measures are needed for a robot cell?

- Can a robot operate in more extreme conditions, for example hot or cold temperatures?

The eBook will be released in quarter 1 of 2024. To have the eBook delivered to your inbox upon publication, please fill out the form below.