Taking IO-Link to the Next Level

Blog post by Ryan Hibbert, Controls Engineer

If you’re wondering what IO-Link is, check out our first IO-Link post, here.

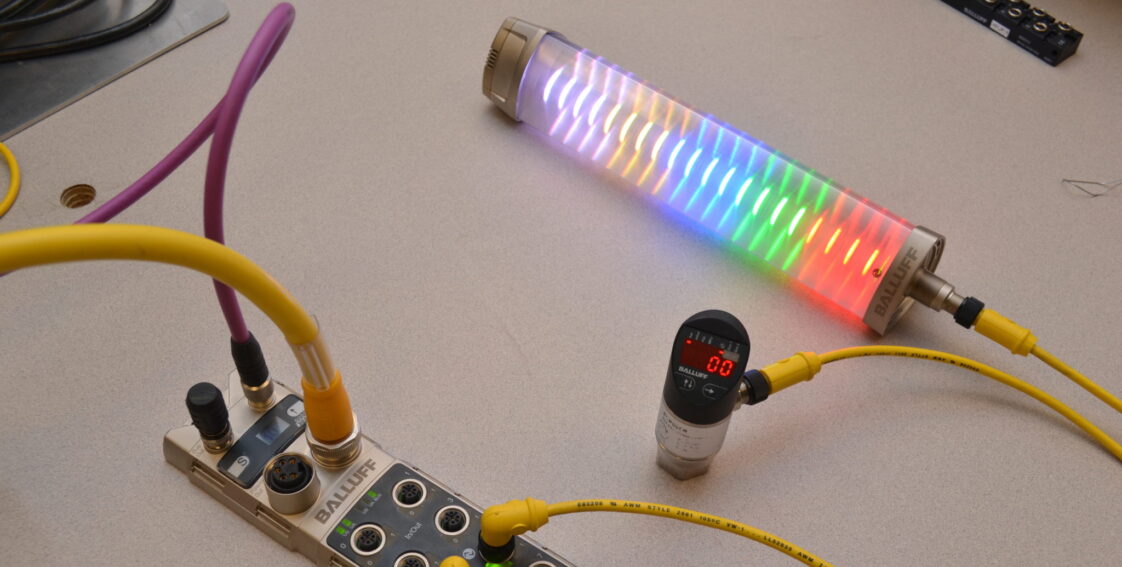

IO-Link is making waves in industrial automation because it makes integrating components so much simpler. We recently worked with Mitsubishi to make these IO-Link devices even more user-friendly.

IO-Link is making waves in industrial automation because it makes integrating components so much simpler. We recently worked with Mitsubishi to make these IO-Link devices even more user-friendly.

With Mitsubishi Electric Technology adding support for interfacing IO-Link technology to its control system, a generic way of integrating these IO-Link devices into a PLC project would be advantageous. The hardware has already been simplified, why not the programming?

By creating a “Master” device function block, an integrator or developer can insert this block quickly and efficiently into a Mitsubishi Electric PLC project and access I/O and diagnostics for each device using IO-Link. This can also be done regardless of the network type (Profibus, ProfiNet, CC-Link IE, etc.).

This master device can handle all process data to/from point-level devices and is also a template for HMI integration to visually see I/O and diagnostics errors (open and short circuit or network errors) for plant floor support personnel. The master function block has all the base information to do I/O and communication, but customization can be done outside the block quickly to conform to the target devices used.

One of the Mitsubishi engineers we had the pleasure to work with calls this master IO-Link block a “game changer” and helps to future-proof development efforts. In future Mitsubishi Electric controls development, these tools and functions for IO-Link Technology can lead to more efficient development and tighter integration with Mitsubishi Electric controls. Even our future Patti Engineers could make use of this to integrate IO-Link into Mitsubishi Electric controls more efficiently.

To catch our upcoming blogs, sign up for our newsletter now.

Related categories: Blog Control Systems Integration